Ningbo Xinbang Technology Co., Ltd. was established in 2004 in Ningbo, Zhejiang Province. It is a provincial science and technology small and medium-sized enterprise specializing in the production of recycled metal resources recycling and downstream product application, a specialized, refined and innovative enterprise, a Zhejiang manufacturing standard enterprise and a green factory enterprise.

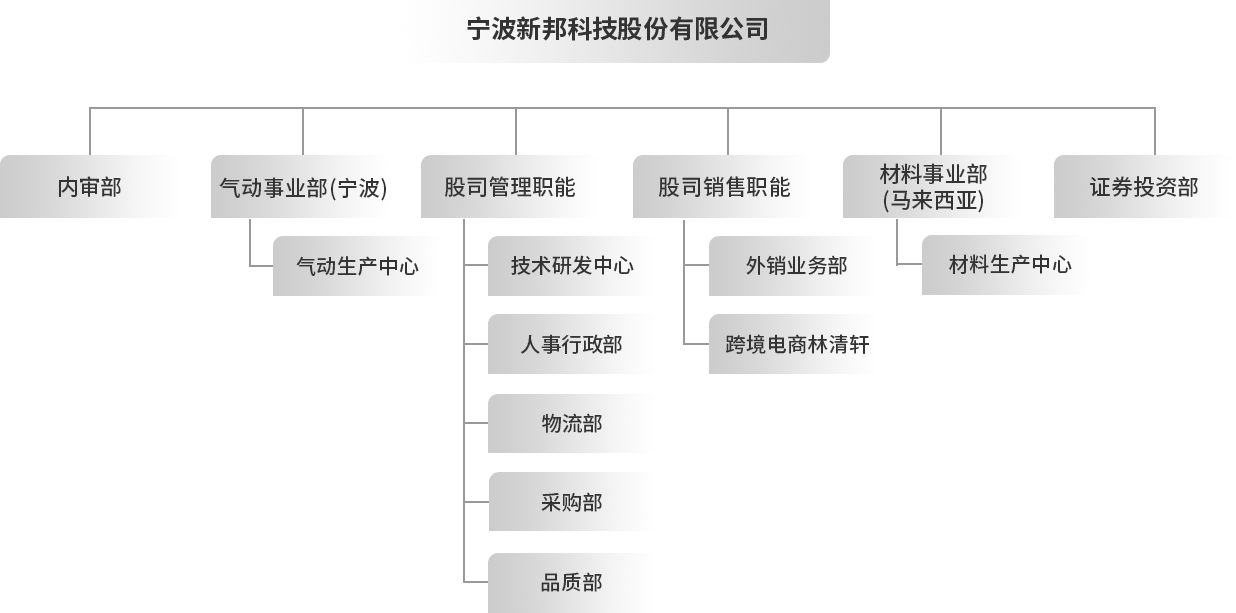

The company mainly engages in the research, development, production, and sales of recycled aluminum ingots, copper rods, zinc ingots, and pneumatic components, as well as hardware and bathroom fixtures. It has formed a business pattern centered on "recycled metals and pneumatic components," with integrated upstream and downstream development. The downstream applications primarily cover hardware and bathroom fixtures, die-cast parts, automotive repair and maintenance, and industrial automation components. The company is actively expanding into downstream application areas such as pneumatic and electric tools, outdoor lighting, and communication equipment, aiming to develop into an integrated full-industry-chain ecological enterprise that encompasses research, supply, production, and sales.

The company now has three production bases in Ningbo, Zhejiang province, Malaysia and Chaohu, Anhui Province. The planned capacity of the company is 280,000 tons of recycled aluminum, 15,000 tons of copper rod and 15,000 tons of zinc alloy per year. At present, the company's two business divisions of recycled materials and pneumatic are actively advancing, while the company is also actively expanding its cross-border e-commerce team and expanding hardware and bathroom fixtures, auto repair and maintenance, household appliances, etc.

As one of the leading companies in China's recycled aluminum and pneumatic industries, Xinbang Technology has already established a certain scale advantage and industrial influence domestically. Under the national policies of carbon peak, carbon neutrality, green and low-carbon development, and circular economy, it actively contributes to regional industrial development, downstream ecological industry application loops, Belt and Road market expansion, and the integration of domestic and foreign trade, making significant contributions to both industry and society.